Fusion energy promises to be a safe, low-carbon and sustainable part of the world’s future energy supply. In recent years, progress in the UK and internationally has demonstrated this potential. At the same time, it has highlighted the significant scientific and engineering challenges that still remain. One of these challenges is developing accurate tritium measurement technology. It is essential to measure and control hydrogen isotopes throughout the fusion fuel cycle. As fusion machines move towards power plant operation, reliable analytical tools become increasingly important. These tools support safe, efficient and continuous fuel management.

As part of this national effort, IS-Instruments Ltd has been working with the United Kingdom Atomic Energy Authority (UKAEA) through its Fusion Industry Programme (FIP). The programme supports the development of ISI’s Gas RAman Detection of Tritium (GRADE) technology.

Demonstrating tritium detection during Phase 2

During Phase 2 of the Fusion Industry Programme, ISI’s gas Raman system successfully detected tritium under operationally relevant conditions. Testing took place at the facilities of project partner, Amentum. This milestone demonstrated the ability of Raman spectroscopy to deliver real-time measurement of hydrogen isotope composition. As a result, it improves visibility and control over fusion fuel processes. Importantly, this achievement represents a key step forward in tritium measurement for fusion. It also marks the transition from feasibility studies to practical application.

A technology shaped by long-term development

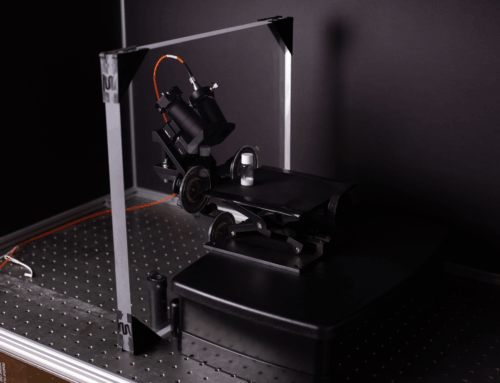

The GRADE system is not a standalone development. Instead, it reflects nearly a decade of continuous evolution, with origins dating back to 2016. Since then, ISI has advanced gas Raman technology through a series of collaborative projects. These projects focused on improving sensitivity and robustness in demanding environments.

A central enabler of this progress is the use of hollow-core microstructured optical fibre. ISI developed and optimised this fibre in collaboration with the Optoelectronic Research Centre. This fibre architecture significantly increases the interaction length between laser light and gas, delivering a stronger Raman signal and improved analytical performance. The fibre architecture increases the interaction length between laser light and gas. Consequently, it delivers a stronger Raman signal and improved analytical performance. This technology underpins Notus, ISIs’ gas Raman instrument platform, which forms the basis of the GRADE system used in fusion fuel applications.

From experimentation to scale-up

Building on the successful outcomes of Phase 2, ISI has now secured Fusion Industry Programme scale-up funding. This funding supports the next stage of GRADE development. Specifically, this phase will focus on:

• Scaling the instrument for continuous operation

• Gathering performance data in operationally relevant environments

• Progressing the system towards commercial readiness for future fusion power plants

Throughout this phase, UKAEA expertise and facilities will continue to support the work. This ensures close alignment with the real technical requirements of fusion machines and fuel cycle operations.

Contributing to the UK fusion ecosystem

The Fusion Industry Programme brings together organisations and industrial partners from across the UK. Its aim is to stimulate innovation and address fusion energy’s most demanding challenges. ISI’s contribution sits within this wider ecosystem. It provides specialist analytical capability that complements advances in fuel handling, materials and system design.

We believe our technology can play a key part in the development of fusion energy by:

• Providing accurate, real-time hydrogen isotope measurement

• Supporting improved control of fusion fuel cycles

• Enabling analytical systems that can transition from experimental use to power plant deployment

As fusion energy moves closer to real-world application, high-precision measurement technologies will be essential. Through continued collaboration with UKAEA and industry partners, IS-Instruments is proud to support the development of tools that help make fusion energy a practical reality.

This project has been supported by the UK Atomic Energy Authority through the Fusion Industry Programme. The Fusion Industry Programme is stimulating the growth of the UK fusion ecosystem and preparing it for future global fusion powerplant market.

More information about the Fusion Industry Programme can be found online: https://ccfe.ukaea.uk/programmes/fusion-industry-programme/