Sustainable Medicines Manufacturing is one of Innovate UK’s flagship Grand Challenge programmes, bringing together major pharmaceutical companies, SMEs, automation specialists, academic centres, and analytical technology developers to reimagine how medicines are manufactured. Within this programme, the Sustainable Future Factory project led by AstraZeneca brings together more than a dozen partners from industry and academia. The consortium aims to build scalable, low-emission, data-driven manufacturing platforms that significantly reduce waste, energy consumption, and environmental impact.

IS-Instruments (ISI) joins this consortium as a specialist provider of advanced spectroscopic Process Analytical Technology (PAT). Although the project is broad, spanning robotics, automation, crystallisation, membrane technologies, and continuous processing, PAT is the unifying mechanism that enables real-time optimisation, regulatory compliance, and sustainable decision-making across every stage of manufacturing.

This article explores the project’s purpose, the technologies being developed, the partners involved, and ISI’s role.

Why the Future Factory Project Matters

Pharmaceutical manufacturing has historically prioritised yield, speed, and quality, but sustainability has become an urgent dimension. As the proposal highlights, medicines manufacturing contributes significant greenhouse gas emissions, with much of the environmental burden embedded in early-stage process development, solvent usage, and energy-intensive purification steps.

Current challenges include:

-

High material usage during early development, where processes may consume grams to kilograms of material to generate a basic understanding.

-

Limited automation, resulting in slow, labour-intensive experimentation.

-

Energy-intensive downstream processing, especially distillation and drying.

-

Fragmented data systems preventing integrated optimisation.

-

Under-used PAT, particularly high-sensitivity optical techniques like Deep-UV Raman.

To address these issues, the Future Factory project embeds sustainability at the design stage rather than retroactively. It focuses on transforming both drug substance and drug product manufacturing, as well as waste valorisation, solvent recovery, and closed-loop process optimisation.

Core Technical Themes of the Sustainable Future Factory

1. Automation, Robotics & AI-Driven Optimisation

The consortium will build advanced automation platforms, including:

-

High-throughput experimentation (HTE) systems capable of running 24/7 autonomous workflows

-

Collaborative robots (“cobots”) to perform complex synthesis and crystallisation tasks

-

Self-optimising reactors guided by model-based and machine-learning algorithms

-

Closed-loop systems that plan, perform, capture, and refine experimental cycles

These systems reduce the material footprint of early development by replacing high-volume, manual experimentation with miniaturised, automated, data-rich experiments.

2. Next-Generation Manufacturing Reactors

A primary objective is to unlock sustainable continuous processing through new reactor types, including:

-

GMP-compliant Taylor-vortex photochemical reactors (up to 10 kg/day production)

-

High shear wet milling for co-precipitated amorphous solid dispersions

-

Predictive modelling tools for spray drying, tablet compression, and polymer-drug interactions

These reactors enable shorter, cleaner routes that avoid thermally harsh or solvent-heavy operations.

3. Sustainable Downstream Processing

Downstream processing is a major sustainability bottleneck. The project will address:

-

Membrane-based separation for biologics and oligonucleotides

-

Solvent recycling (including a real-time PAT-controlled acetic acid recovery system at AZ’s Zoladex plant, where 5,500 L of waste is generated annually)

-

Catalyst and precious-metal recovery

-

Waste minimisation and circular economy strategies

These innovations aim to achieve significant reductions in solvent use, hazardous waste generation, and energy consumption.

4. Cross-Cutting PAT and Digital Foundations

Work Package 4 focuses entirely on modernising PAT:

-

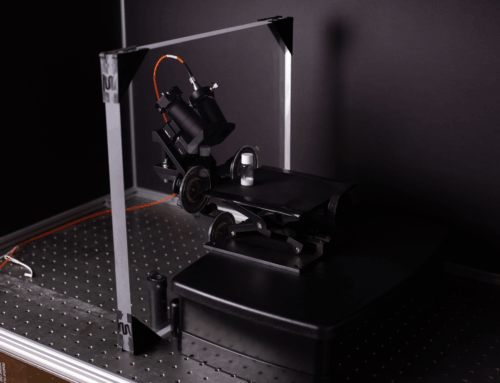

Development of a compact, affordable Deep-UV Raman system

-

Integration of UV, Raman, A-TEEMs, IR, HPLC, GC, and imaging

-

Automated PAT method development linked directly to robotics

-

Real-time spectral analysis for closed-loop optimisation

-

Multisensor fusion for process understanding and control

This is where ISI’s role becomes central.

The proposal emphasises that robust, high-resolution analytical tools are critical for enabling autonomous systems, sustainable process optimisation, and regulatory acceptance.

Consortium Partners

The project is led by AstraZeneca UK, with a consortium spanning the entire value chain:

Pharmaceutical & Biopharma Companies

-

AstraZeneca (lead)

-

GlaxoSmithKline (GSK)

-

Bristol-Myers Squibb

-

Asymchem

-

Pharmaron

-

Exactmer

Technology Providers & SMEs

-

Labman Automation

-

IS-Instruments

-

Indicatrix Crystallography

-

CoreTech Sciences

-

Caledonian Photonics

-

Britest

Academic Partners

-

University of Leeds

-

University of Liverpool

-

Newcastle University

-

University of Nottingham

-

Queen Mary University of London

-

University of Cambridge

RTOs

-

CPI (Centre for Process Innovation)

This collective expertise ensures that innovations progress from TRL 6/7 to deployment-ready TRL 9 solutions.

Why IS-Instruments Is Part of the Future Factory Project

Future Factory is broad and multi-disciplinary; therefore, ISI’s inclusion is both logical and strategic.

ISI brings:

1. Proven Capability in High-Sensitivity Optical PAT

ISI’s Deep-UV Raman (DUVRR) systems provide:

-

Exceptional molecular specificity

-

Fluorescence suppression

-

Sensitivity to structural changes in APIs, intermediates, and biologics

-

Capability for inline or in situ monitoring

These features are crucial for real-time characterisation in demanding environments such as:

-

Self-optimising reactors

-

Photochemical flow systems

-

Crystallisation platforms

-

Continuous downstream purification

2. Established Track Record Identifying and Quantifying Biological Materials

2. Established Track Record Identifying and Quantifying Biological Materials

ISI has previously demonstrated:

-

Raman measurement of complex biological substances, including MAbs and DAbs

-

Bioreactor purification monitoring capabilities, tracking feedstock to product materials

This experience directly aligns with the Sustainable Future Factory’s PAT ambitions.

3. A Key Role in Developing a Compact Deep-UV Raman System

The proposal specifies the creation and deployment of an affordable, compact Deep-UV Raman spectrometer as a cornerstone PAT tool for real-time monitoring and AI-driven optimisation.

ISI is uniquely qualified to lead this workstream, given:

-

World-leading expertise in DUV Raman instrument design

-

Ability to engineer robust systems for harsh industrial environments

-

Experience integrating optical sensors into automated workflows

-

History of partnerships with AstraZeneca, CPI, and other consortium partners

4. Essential Contribution to Data-Rich, Sustainable Manufacturing

Spectral PAT provides the data backbone needed for:

-

Continuous-feedback control loops

-

Predictive modelling and mechanistic understanding

-

Sustainability metrics (PMI, solvent usage, waste profiling)

-

Optimisation of reaction conditions, crystallisation, and purification

Without high-quality PAT, automation and AI cannot deliver sustainable outcomes.

Building the Factory of the Future

The Sustainable Future Factory project represents one of the most ambitious shifts in UK pharmaceutical manufacturing. By uniting robotics, automation, advanced reactors, membrane technologies, and cutting-edge PAT, it aims to deliver more efficient, resilient and dramatically more sustainable manufacturing systems.

IS-Instruments is proud to contribute our expertise in high-resolution optical spectroscopy to a programme poised to reshape the sector. Through innovations in Deep-UV Raman and integrated PAT, ISI will help ensure that the factories of the future are informed by real-time molecular insight, maximising efficiency while minimising environmental impact.