On the 7th of May, the UK Atomic Energy Authority (UKAEA) held a showcase day to highlight the successes achieved under its Fusion Industry Programme (FIP). IS-Instruments’ Jessica Gabb presented the results of the GRADE – Gas RAman DEtection of tritium project, accompanied by Dr Rhea Sam and Dr Michael Foster.

UKAEA launched the FIP programme in 2022 to accelerate growth and commercialisation of the UK’s fusion energy sector. It fosters collaboration between public and private organisations to advance fusion innovation. The showcase united innovators, suppliers, UKAEA staff, and stakeholders to review progress and highlight emerging fusion technologies.

The Tritium Challenge

Measuring tritium in deuterium-tritium (D-T) plasma reactions remains a significant challenge in fusion. Tritium management — production, storage, and accountancy — is critical to nuclear fusion’s commercial viability. Real-time tritium monitoring ensures safe, optimal reactor performance across pressures and concentration ranges. Systems must distinguish hydrogen isotopologues such as deuterium, deuterium hydride, and tritium deuteride. However, due to tritium’s radioactivity, its management presents significant technical and safety challenges.

Conventional tritium measurements use multiple, often offline techniques conducted in controlled laboratory environments. These methods rely on complex sampling, limiting efficiency and responsiveness. Under the GRADE project, ISI and partners developed a gas-phase Raman spectroscopy system for real-time tritium measurement. The system provides a compact, reliable, user-friendly, and economically advantageous single-platform solution.

The Gas Raman System

The system was initially conceived in 2016 during a collaboration with Amentum and the University of Southampton’s Optoelectronic Research Centre (ORC). The latter has earned worldwide recognition for specialising in the design of hollow-core microstructured optical fibres (HCFs). Raman is a long-established and effective technique for measuring solids and liquids. However, the diffuse nature of gases makes them more challenging to measure. Hollow-core microstructure fibres are a way to overcome this. In this setup, the system fills the hollow fibre with the target gas and transmits the laser through it, extending the interaction path length. This configuration enables the detector to collect a clearer Raman signal.

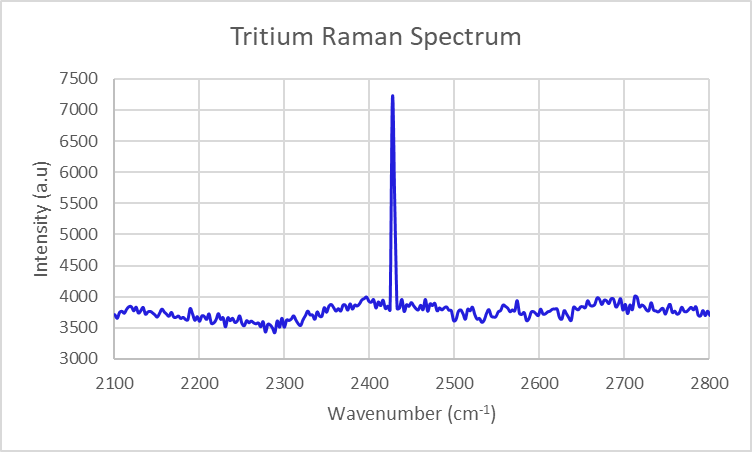

The three organisations continued their collaboration to develop the system under the first FIP-supported GRADE project. During this phase, the team successfully demonstrated the system’s ability to distinguish deuterium, deuterium hydride, and hydrogen in gas samples. Unlike alternative systems that rely on post-processing software, this system directly generates high-quality raw data with excellent peak separation.

Neutron radiation testing took place at ISIS Nile. Both tests yielded successful outcomes with no silica-based radiolytically induced attenuation detected. In April 2025, the system reached a significant milestone: the successful detection of tritium at Amentum’s Science and Engineering laboratories at Birchwood.

Jessica Gabb (MCHEM), ISI’s project lead, said:

“Successfully measuring tritium is a significant breakthrough, demonstrating the potential of our Raman system to become an integral part of future fusion fuel cycle diagnostics. It has shown the potential to provide precise isotopic analysis at various points across a reactor system without the need for offline handling or multiple measurement methods. This system could conceivably become a core component for making tritium measurements – a fundamental factor for a commercially viable fusion future.”

Looking To The Future

Dr Rhea Sam sees plenty of potential for the system: “The team still has work to do to make the system commercially viable, scalable, and widely deployable. However, developing a robust, tritium-compatible instrument that detects multiple gas species in varied conditions will greatly benefit the fusion industry. Furthermore, if the team succeeds in creating a handheld version, the instrument will truly transform fusion monitoring.”

Dr Michael Foster commented, “The FIP Showcase Day was an excellent opportunity to meet other scientists and stakeholders in this venture to make fusion a reality. The GRADE project perfectly demonstrates how the Fusion Industry Programme accelerates innovation, closes technical gaps, and advances technologies toward deployment in real fusion environments.”

GRADE 3 is due to commence in July 2025.

This project has been supported by the UK Atomic Energy Authority through the Fusion Industry Programme. The Fusion Industry Programme is stimulating the growth of the UK fusion ecosystem and preparing it for future global fusion powerplant market. More information about the Fusion Industry Programme can be found online: https://ccfe.ukaea.uk/programmes/fusion-industry-programme/