The InSPIREmed project – Integrated Spectroscopy and Photonics for Increased Productivity and Resource Efficiency in Medicines Manufacture – is a major UK initiative aimed at redefining how modern pharmaceuticals are developed and manufactured. Funded through the Innovate UK Sustainable Medicines Manufacturing Programme (SMMIP), the project brings together a consortium of world-leading organisations to develop a new generation of high-performance, integrated photonic Process Analytical Technology (PAT) systems.

These systems will support real-time monitoring and control of critical pharmaceutical operations, enabling cleaner, more energy-efficient, and more reliable manufacturing processes.

IS-Instruments (ISI) is a core technology partner in this programme, contributing state-of-the-art Deep-UV Raman spectroscopy solutions that provide the molecular sensitivity needed for next-generation sustainable bioprocessing.

Why InSPIREmed Matters

The pharmaceutical sector is under increasing pressure to improve the sustainability, resilience, and efficiency of its manufacturing processes. Many current methods are limited by:

-

Slow or infrequent offline analysis

-

Energy-intensive operations such as freeze-drying

-

Limited visibility of molecular changes in complex biological systems

-

A lack of integrated, real-time decision tools

-

Quality risks associated with batch-based processing

To address these challenges, the industry requires robust, high-resolution PAT tools capable of operating in demanding environments while delivering real-time, high-fidelity data.

InSPIREmed focuses specifically on integrating advanced photonics, including Raman, deep-UV Raman, mid-IR, and particle-scale optical sensing, with digital control and automation. By doing so, the project will create a unified analytical framework that supports:

-

Continuous verification of critical quality attributes (CQAs)

-

Reduced energy and solvent consumption

-

Faster process development and optimisation

-

Greater manufacturing resilience and product consistency

A World-Class Consortium

The strength of InSPIREmed lies in its multidisciplinary consortium, which includes major pharmaceutical manufacturers, leading photonics groups, national laboratories, regulatory bodies, and digital technology experts.

Key partners include:

Photonics & Measurement Specialists

-

IS-Instruments (ISI)

-

Sparta Biodiscovery

-

Dyneval

-

Particology

-

Vortex Optical Coatings

- Caledonian Photonics (subcontracted)

These groups develop the optical sensing and characterisation technologies that underpin InSPIREmed’s PAT framework.

Industry & Manufacturing Partners

-

Cytiva

-

CPI (Centre for Process Innovation)

- GSK (GlaxoSmithKline)

These organisations provide industrial bioprocess platforms for validation and deployment, ensuring the sensors developed are ready for real-world application.

Regulatory, Standards & Metrology Bodies

-

MHRA (Medicines and Healthcare products Regulatory Agency)

-

NPL (National Physical Laboratory)

-

BSI (British Standards Institution)

Their involvement ensures the analytical tools and data structures developed are compatible with future regulatory guidance and GMP expectations.

Digital & Academic Partners

-

University of Strathclyde

-

Optimal Industrial Automation

-

VisionMetric

They support advanced modelling, multimodal data fusion, control strategies, and the development of computational frameworks for automated decision-making.

Together, this consortium provides the whole chain from sensor development to deployment in regulated industrial settings.

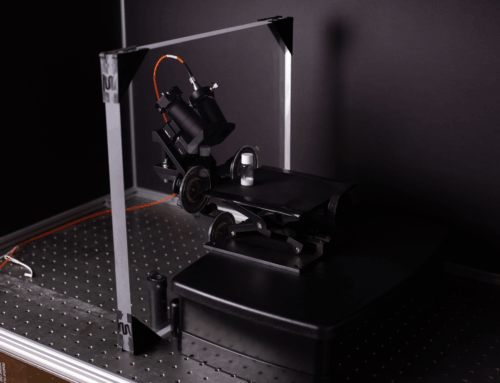

ISI’s Role: High-Sensitivity Deep-UV Raman for Real-Time Bioprocess Monitoring

ISI’s contribution to InSPIREmed focuses on developing compact, high-sensitivity Deep-UV Raman (DUVRR) instrumentation for use in challenging bioprocess environments. Deep-UV Raman provides resonance enhancement of biomolecular signals, allowing ultra-sensitive detection of:

-

Protein conformation and structural integrity

-

Aggregation and degradation pathways

-

Excipient interactions

-

Subtle physicochemical changes during freeze-drying and perfusion processes

This level of sensitivity is essential where traditional NIR, MIR, or visible-range Raman systems struggle due to fluorescence interference or low signal strength.

Two key InSPIREmed application areas for ISI technology include:

1. Real-Time Monitoring of Freeze-Drying

Freeze-drying (lyophilisation) is one of the most energy-intensive stages in biopharmaceutical production, and current monitoring techniques often lack molecular resolution. ISI’s DUVRR system will allow:

-

Through-vial, non-invasive monitoring

-

Tracking of structural changes in proteins and excipients

-

Identification of endpoints and instability during drying

-

Optimisation to reduce cycle times and energy consumption

2. Monitoring Monoclonal Antibody Perfusion

Continuous perfusion processes require precise control of protein quality attributes. ISI’s DUVRR platform will support:

-

Inline structural characterisation of biomolecules

-

Early detection of aggregation or degradation

-

Real-time optimisation of nutrient feeds and harvest cycles

-

Improved yield with reduced water and energy use

Why ISI Was Selected: Technical Foundations from ATLAS-BIO and Digital_Lyo

ISI’s involvement in InSPIREmed builds directly on the technical successes of two previous programmes:

Digital_Lyo

During Digital_Lyo, ISI developed a robust through-vial Raman monitoring system capable of detecting molecular transitions during freeze-drying in real time. This proved that photonics could provide meaningful, inline molecular insight in low-temperature, reflective, and highly dynamic environments.

ATLAS-BIO

This programme demonstrated ISI’s ability to apply deep-UV Raman to complex biologics, including protein structural analysis, aggregation monitoring, and characterisation of cell-culture media.

Together, these projects established:

-

Proven capability in DUV Raman instrument development

-

Expertise in integrating photonics with automated control systems

-

Understanding of bioprocess-specific analytical challenges

-

Validated hardware ready for industrial progression

This track record positioned ISI as a natural contributor to InSPIREmed’s photonic PAT workstreams.

Shaping the Future of Sustainable Bioprocess Manufacturing

InSPIREmed represents a significant step forward for the UK’s medicines manufacturing sector. By uniting advanced photonic sensing, digital modelling, and real-time control, the project will enable:

-

More efficient biologics production

-

Shorter and cleaner freeze-drying cycles

-

Reduced energy and solvent usage

-

Improved product consistency and process reliability

-

Wider adoption of automated and continuous manufacturing approaches

ISI is proud to contribute its specialist Raman expertise to this ambitious programme and to work alongside a consortium committed to delivering the next generation of sustainable, intelligent biomanufacturing technologies.