The nuclear sector urgently needs technology that can identify hazardous substances from a safe distance. Such capability reduces human exposure and minimises risk. Since 2018, IS-Instruments has worked in nuclear decommissioning to address this challenge. In partnership with i3D Robotics, ISI developed Callisto, a system that combines stereo camera technology and Raman spectroscopy. Together, these systems create 3D scene maps and identify the chemical composition of materials within them.

Building on this experience, ISI and Jacobs have now developed a new class of spatial heterodyne Raman spectrometer.

This innovation enables reliable Raman measurements within radioactive environments – a significant breakthrough for the sector.

Why It Matters

Raman spectroscopy is a proven method for identifying radioactive substances. It can detect alpha and low-energy gamma emitters even in the presence of intense high-energy radiation. However, conventional Raman instruments cannot operate effectively within radioactive zones. They must remain outside the field, limiting precision and scope. That limitation is now changing.

The new ISI–Jacobs system allows Raman measurements to be made safely and accurately inside hazardous environments.

A Smarter, Safer Design

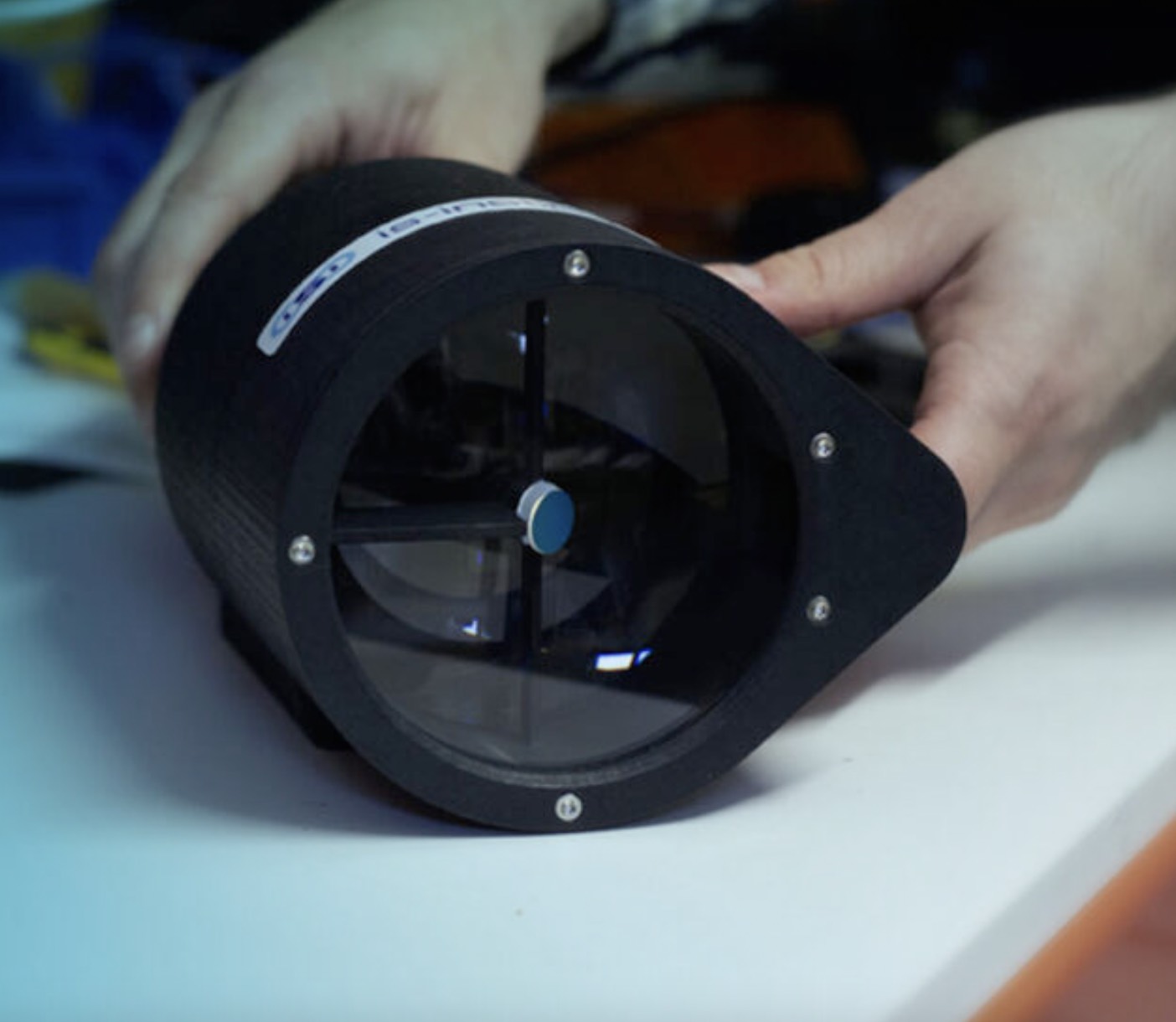

The Raman probe can be mounted on multiple platforms, including robotic arms and remotely operated vehicles (ROVs). Operators can position it up to three metres from the target sample. Power and data are transmitted through an umbilical cable that also manoeuvres the probe. Meanwhile, a shielded optical fibre carries the Raman signal back to the spectrometer outside the radioactive zone. This configuration keeps the complex and costly sensing equipment protected. As a result, it reduces both waste and operational risk. The probe itself was purpose-built for radiative deployment. It features a streamlined profile and materials that are easy to clean and decontaminate.

From LIDAR to Stereo Vision

ISI initially integrated LIDAR technology to position the probe precisely. Although effective, this approach faced challenges with repeatability. Therefore, the team adopted a stereo vision system from i3D robotics, leaders in 3D imaging technology. This upgrade significantly improved positioning accuracy and operational stability.

From Concept to Deployment

The collaboration originated through an Innovate UK-funded Game Changers competition supported by FIS360. Subsequently, the project advanced under Jacobs’ participation in the UK Integrated Innovation for Nuclear Decommissioning (IIND) competition. Innovate UK, the Nuclear Decommissioning Authority, and Sellafield Ltd supported that initiative.

Through successive project stages, the system progressed from Technology Readiness Level 3 (TRL 3) to TRL 8. It has been tested successfully in a representative environment. An independent expert panel classified the technology as “high maturity.” They confirmed its strong potential for in-cell characterisation during decommissioning planning and operations. The full system will soon be deployed at Sellafield during the decommissioning of an active separation cell.

When operational, this Raman technology will be among the first to deliver in-cell analysis directly within a nuclear environment.

Learn More

For further details, read these articles in Nuclear Engineering International:

Jacobs deploys Raman spectroscopy to identify radioactive contamination