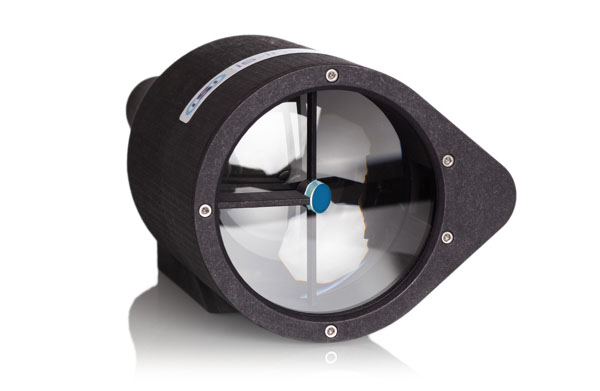

RP1000 Raman Probe for Stand-Off Measurements

RP1000 Standoff Raman Probe

Our Standoff Raman probe can measure from distances up to 3 meters from the target.

These probes use the highest quality optical filters to suppress unwanted laser light and have focal lengths from 50 mm up to 3 m.

Product Specifications

RP1000 Raman Probe for Standoff Measurements

These probes are designed to work seamlessly with the ISI range of HES spectrometers.

Noted for their highest throughput characteristics (100-fold increase in throughput over current conventional systems). This allows for maximum light collection even at a distance. Our fibre-coupled Standoff Raman probes can be fitted to a robotic arm for deployment by ROV, making them ideal for remote sensing in hazardous environments.

This probe is designed to operate with the HES2000 spatial heterodyne Raman spectrometer. Operating at a 1000 mm standoff distance from the 100mm diameter window, the probe will facilitate non-destructive interrogation of target samples to capture material-specific Raman spectra.

Our Raman probe is being used in nuclear decommissioning to remove the human element from detecting substances in gloveboxes.

Features:

- Continuous frame and single frame capture options

- FVB/2D modes

- Image, FFT and spectrum display options

- Frame averaging

- Peak Labelling

- Dark image subtraction

- Spectra overlay function

Standoff Raman Probe Specification:

The specifications below are for the standard RP1000. However, the unit is customisable to operate between 500 mm and 1500 mm standoff distances and may be adapted to operate at alternative Raman excitation wavelengths.

| Feature | Detail |

|---|---|

| Raman operating λ | 785 nm |

| Configuration | Mirrored obscuration and lens combination confocal |

| Standoff distance (from 100mm diameter window) |

1000 mm |

| Laser fibre connection | FC/PC |

| Spectrometer fibre connection | SMA |

| Dimensions | L: 360mm (inc. fibre gland) Max W: 140mm |

| Mass | ~ 1.8 kg |

Applications include:

- Quality control during industrial manufacturing processes

- Process monitoring through inspection ports

- Material characterisation in hazardous locations

- Composition monitoring in Ceramics

- Deployment in nuclear environments

- Robotic-deployed area characterisation/material identification