In high-precision optical systems, alignment isn’t optional; it’s essential.

Even minor shifts can impact performance — especially in spectroscopy, where lasers must precisely focus to detect chemical signatures. If the system doesn’t meet this requirement, the measured signals will show a poor signal-to-noise ratio. This could potentially lead to weak or missed peaks, resulting in false or incomplete conclusions from the data analysis. Recognising this challenge, Dr Alex Poppe, a senior software engineer at IS-Instruments (ISI), developed an intelligent algorithm that automates the laser alignment process. Laser auto-alignment saves time and maintains performance in environments with limited or hazardous human access.

Smarter, Faster Alignment

Dr Poppe conceptualised the algorithm in a couple of days and spent a couple of weeks implementing and testing. After conversion to an executable format for integration with LabVIEW, it was deployed to run with ISI’s gas Raman spectrometer. Its job is to automatically realign the laser to the point of highest optical power, without human input. Piezo actuators move a lens to align the spectrometer, steering the laser spot relative to the hollow-core fibre until it reaches the position that maximises laser power. A power meter identifies this optimal alignment.

A standard way to align a spectrometer is to perform a raster scan across the entire field of view of the fibre cross-section. This maps the entire laser power “landscape” to determine the optimal position for alignment.

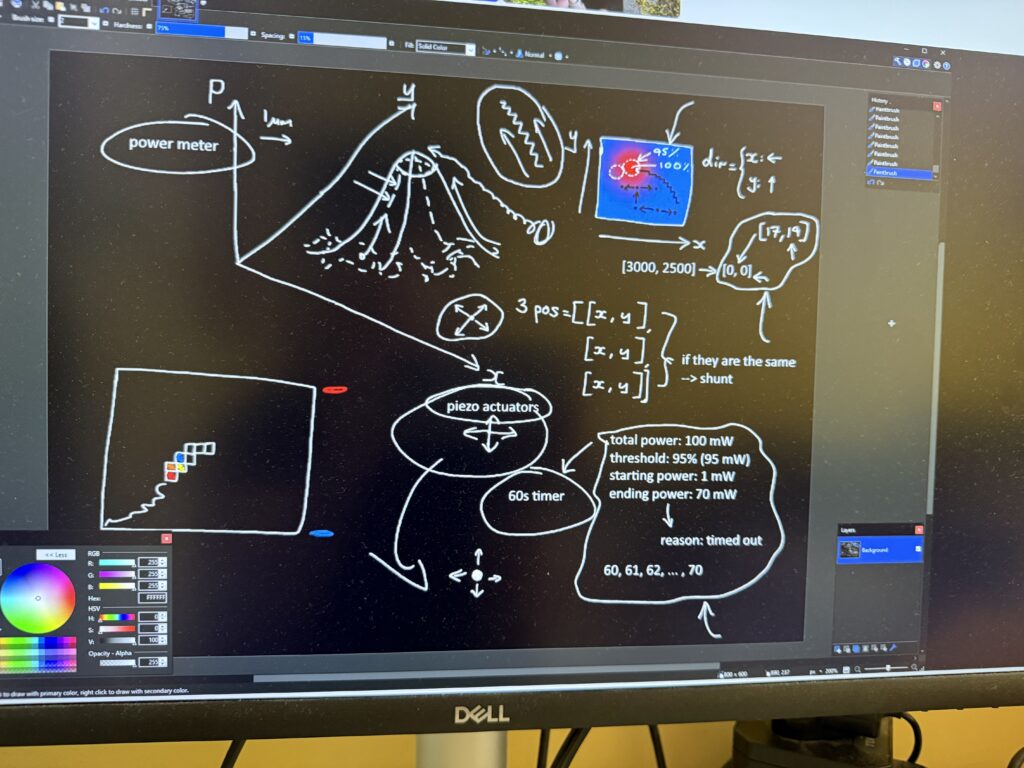

The raster scan approach, whilst effective, is prohibitively slow. Hence, from a sustainability perspective, another alignment algorithm was necessary. Dr Poppe and Charles Warren, a fellow software developer, brainstormed this new algorithm (see the image below), and from an original concept, produced a novel geometry that is both fast and efficient.

The Algorithm

“I designed the algorithm to be robust enough to operate even when background noise found at lower power levels makes signal detection challenging,” says Dr Poppe. “We included a fallback strategy; if the system can’t find a clear maximum, it ‘shunts’ the laser to a new region and begins again. That allows us to operate in more complex or degraded environments.”

The algorithm can be succinctly summarised as performing a “zigzag” pattern. From an initial starting point, it alternates between horizontal (X) and vertical (Y) shifts, as it attempts to move “uphill” in the laser power landscape towards a target power level. The team implemented redundancy to handle cases of extreme misalignment, where the algorithm would otherwise have failed to align within the allotted time limit. This was achieved by “shunting” the laser to a new location, allowing it to escape from a local maximum. It then recommences the zigzagging pattern.

Each time the laser activates, the system reruns the alignment algorithm to quickly realign the spectrometer to its optimal level. This is possible as the natural drift in laser power is minimal over short intervals.

It is challenging to quantify the time savings from this algorithm compared with the raster scan. Either algorithm could, in theory, begin at an optimal power, rendering such a comparison meaningless. However, this new algorithm will, on average, align significantly faster than a standard raster scan, as most of its movements are towards a higher laser power. Conversely, a raster scan must meticulously move to every position until it reaches an optimal point. Thus, many of the movements it makes may be inefficiently moving to a lower laser power than it was previously.

Built for Hostile Environments

ISI deploys Raman spectroscopy in hazardous environments and has extensive experience doing so. A significant advantage of the auto-alignment algorithm is that it can function without manual adjustment. This makes it ideal for remote deployment in hazardous environments.

This algorithm has already proven helpful in the GRADE project, funded by the UK Atomic Energy Authority as part of its Fusion Industry Programme (FIP). This programme is encouraging the development of fusion energy instrumentation and technologies to drive the industry’s growth. ISI, with the Optoelectronics Research Centre and Amentum, is developing a gas Raman spectrometer to identify isotopologues of hydrogen, including tritium. This radioactive variant is crucial to fusion research.

“The radioactive environment where the gas Raman instrument operates provided an ideal testing ground for the laser alignment algorithm. In the nuclear sector, there is a strong effort to eliminate human operators, and this new algorithm supports this goal.” – Jessica Gabb, Scientist & ISI Project Manager for GRADE.

Looking Ahead

Compared to older scanning methods such as the raster scan, which is slower and more intrusive, Dr Poppe’s approach is faster and more adaptive. ISI is now exploring combining this method with spiral-scan models to further accelerate alignment.