Raman Spectroscopy for Gas-Phase Analysis

Raman spectroscopy is a long-established, non-destructive chemical analysis technique. It provides detailed compositional information and can distinguish between allotropes of the same material. Traditionally, Raman spectroscopy works best for solids and liquids. However, the weak Raman scattering effect makes gas analysis more challenging due to the diffuse nature of gaseous targets. Therefore, many laboratories use alternative techniques, such as Fourier Transform Infrared (FTIR) spectroscopy and Gas Chromatography (GC).

Both FTIR and GC are mature, proven technologies. Nevertheless, each method has limitations. FTIR requires an additional analyser to identify homonuclear diatomic molecules. GC systems, although accurate, are bulky, costly, and complex. They demand highly trained operators to run measurements and interpret results. Moreover, GC requires prior selection of columns and detectors based on expected gases, which restricts flexibility.

A New Approach from IS-Instruments

IS-Instruments has developed a Raman instrument capable of characterising substances in gaseous form. Previously, Raman measurements of gases required techniques to maximise signal collection. Researchers have used sample pressurisation, high-power lasers, or both, to strengthen the signal. Increasing the optical path length through the gas also enhances the interaction between the laser and the gas. For example, silver-coated capillaries and mirrored chambers allow the laser to reflect multiple times through the sample. These methods increase the interaction path length, yet sensitivity often remains limited.

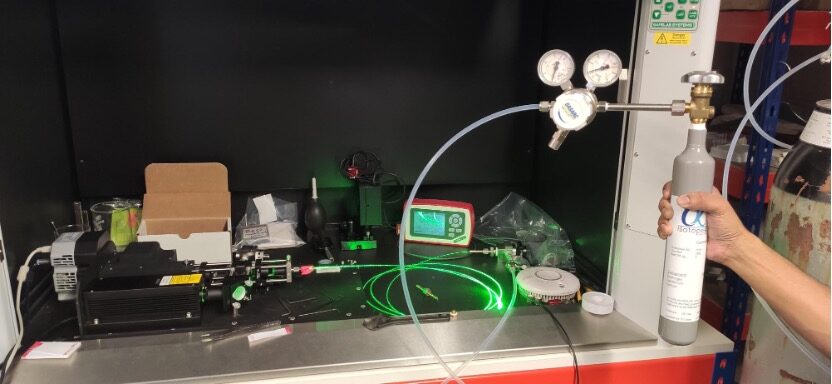

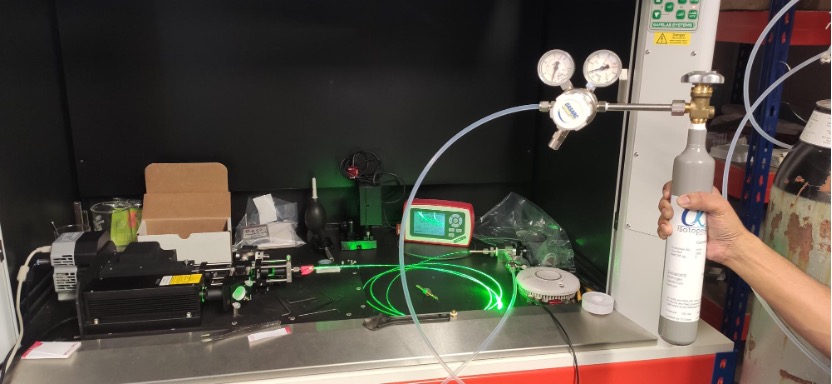

To overcome this hurdle, IS-Instruments developed a hollow-core microstructured optical fibre (HC-MOF) Raman instrument. In this system, the hollow fibre fills with the target gas while the laser transmits through the fibre core. This unique fibre guidance mechanism maintains efficient laser transmission over long distances. As a result, it enables strong laser-gas interaction and significantly improved sensitivity to gas species.

Image showing show instrument layout, hollow core fibre, gas cell block, supply pipework, regulator and sample gas bottle

Collaborative Development and Real-World Applications

The instrument evolved through multiple projects in collaboration with the Optoelectronic Research Centre (ORC) at the University of Southampton and Jacobs. Both organisations support industries where accurate gas analysis is vital, including nuclear, oil and gas, and environmental sectors. These sectors often require on-site gas composition analysis to reduce contamination risk and protect human operators. Therefore, a compact Raman-based instrument offers a valuable and portable alternative to laboratory-based analysis.

IS-Instruments has demonstrated the system’s ability to deliver rapid, repeatable, on-site measurements. It can detect component concentrations as low as 0.04%, using HC-MOF as the gas-sensing medium.

Supporting Net Zero Goals

The gas Raman instrument has been used to monitor hydrogen blending within natural gas pipelines. This research directly supports the UK’s goal of achieving net-zero carbon emissions by 2050. Heating contributes approximately 37% of the UK’s current carbon emissions. Reducing natural gas content by blending with hydrogen offers one practical route to lower emissions. According to the Energy Networks Association, blending 20% hydrogen into the gas grid could reduce emissions equivalent to those of 2.5 million cars per year. Importantly, this change requires no modification to existing gas-burning systems. The plan is undergoing testing and is subject to a final decision by the UK Government in the UK Government Hydrogen Strategy, which will be finalised in 2023. However, the blending process demands continuous monitoring to maintain a safe and consistent gas mixture. This instrument provides an accurate, real-time solution for this critical task.

Foundation Industries and Environmental Impact

The instrument has also been tested within the Foundation Industries: Metals, Glass, Ceramics, Cement, Chemicals, and Paper. These sectors account for roughly 10% of the UK’s total carbon emissions. Their production processes, largely unchanged since the Industrial Revolution, remain highly energy-intensive. Each industry must monitor and report greenhouse gas output to meet environmental regulations. These gases include carbon monoxide, carbon dioxide, nitrogen oxides, sulphur oxides, and methane. The gas Raman instrument identified multiple gas species simultaneously, including homonuclear diatomic variations. Consequently, it offers industries a compact, cost-effective, and precise solution for emissions monitoring.

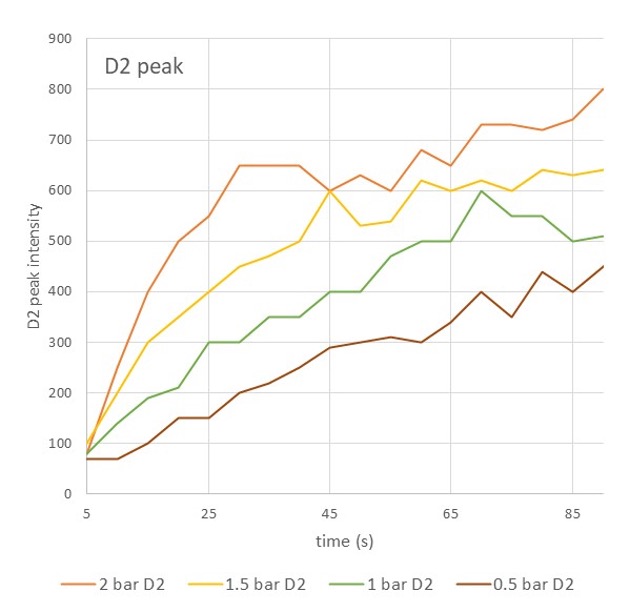

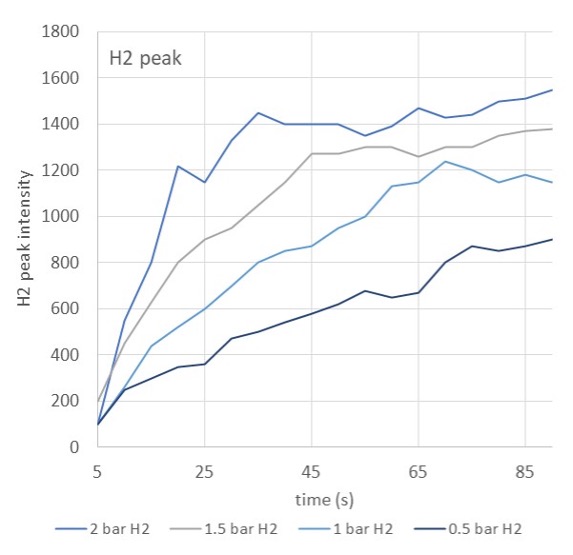

H2 /D2 peak intensity vs. fill time using 4 pressures: 0.5, 1.0, 1.5 and 2.0 barg.

Future Use in Nuclear Fusion

Another key application lies in nuclear fusion research, where accurate monitoring of hydrogen isotopologues is essential. The instrument has already identified and quantified hydrogen, deuterium, and deuterium hydride. Future testing aims to detect tritiated species during later development stages. Therefore, this instrument could play an important role in supporting fusion research and energy innovation.

For further reading on the development of our gas phase Raman instrument: https://analyticalsciencejournals.onlinelibrary.wiley.com/doi/full/10.1002/jrs.6195