Innovate UK Emerging and Enabling Technologies – 26-month project: 01.02.18 to 31.03.20

IS-Instruments, in collaboration with the Optoelectronics Research Centre (ORC) at the University of Southampton and Jacobs (formerly Wood), has developed a novel gas-sensing method. It uses a Raman-based spectroscopic technique employing hollow core microstructured optical fibres.

This 26-month Innovate UK project under the Emerging and Enabling Technologies programme has advanced Raman technology for high-sensitivity gas analysis in the nuclear sector.

Background and Challenge

Raman spectroscopy is a proven chemical analysis method with excellent selectivity. It identifies a wide range of solid and liquid samples by measuring their unique molecular fingerprints. However, Raman scattering is inherently weak. As a result, sensitivity can be low, particularly when analysing gases. Gas-phase species are diffuse, making photon interaction and scattering even less efficient. To overcome this limitation, scientists must maximise the optical path length through the gas sample. Doing so increases the number of excitation photons that interact with scattering centres, enhancing the Raman signal. Consequently, this produces a stronger and clearer spectral fingerprint for identification.

Innovation: Hollow-Core Microstructured Optical Fibres

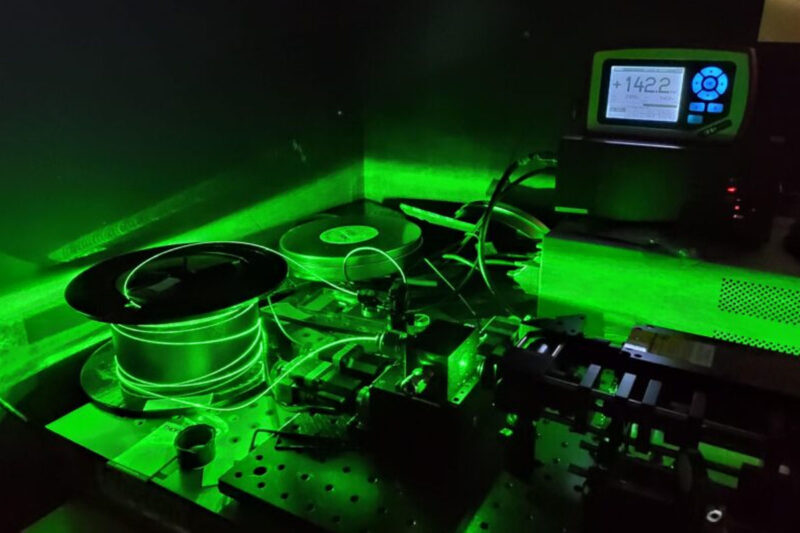

One highly effective solution is to use hollow core microstructured optical fibres (HC-MOFs). In this system, the target gas is drawn into the fibre’s internal channel. A laser then excites the gas molecules, and a dispersive spectrometer records the light scattered by them. Coupling optics ensures precise alignment and efficient signal capture. This design substantially increases the interaction path length while maintaining excellent optical control. As a result, Raman spectroscopy can now achieve far higher sensitivity for gas-phase analysis.

Through this Innovate UK collaboration, IS-Instruments and partners demonstrated that HC-MOF technology significantly boosts Raman sensitivity. Moreover, it retains the selectivity advantage that distinguishes Raman spectroscopy from other analytical techniques.

Project Results and Performance

During performance testing, the instrument successfully measured multiple gas species both individually and simultaneously. It achieved high sensitivity across a range of concentrations. Therefore, this system represents a significant step forward in real-time gas characterisation. The RAGNUSMOF project confirmed that Raman-based gas analysis can operate efficiently in industrial and nuclear settings. It also demonstrated that the technology can be adapted for diverse environments requiring precise gas identification.

Commercial Opportunity

A highly sensitive and selective Raman gas measurement system offers strong commercial potential across multiple industries. Currently, gas chromatography (GC) dominates the gas-analysis market, valued at approximately $3 billion annually by 2022. However, Raman-based solutions can match, and even exceed, GC sensitivity while offering greater selectivity and faster results. Furthermore, Raman systems enable in situ gas measurement without the need to collect samples for off-site analysis. This reduces total measurement time and minimises contamination risk. In addition, the technique supports pressurised gas analysis up to 120 bar without pressure-reduction stages. It also enables multi-channel detection, using several HC-MOF systems placed in different regions to map gas distribution in real-time.

Looking Ahead

IS-Instruments plans to bring its HC-MOF-based Raman gas-sensing system to market. The technology promises unique deployment flexibility, exceptional sensitivity, and unmatched chemical selectivity. Therefore, it offers a viable and innovative alternative to conventional GC-based solutions across nuclear, oil and gas, environmental, automotive, and biopharmaceutical sectors.

Read the publication here.